Any time an engine has more than 6 cylinders, it will be manufactured as a V engine as a straight 8 or straight 10 will not fit in the engine compartment of the average vehicle today and I don't know of any V4 engines in use on vehicles these days.

Inline Engine

The inline engine also called I (eg. I6=inline 6 cylinder) because all of the cylinders are inline with each other and the pistons are vertical.

An inline engine can easily accommodate an odd number of cylinders such as 5 cylinder engine or the 3 cylinder engines that may be used in small fuel efficient models.

An inline 6 will be cheaper to build than a V6 engine and there can be less complications in this 6 as there is one engine head for the timing belt or chain to connect to.

V Engine

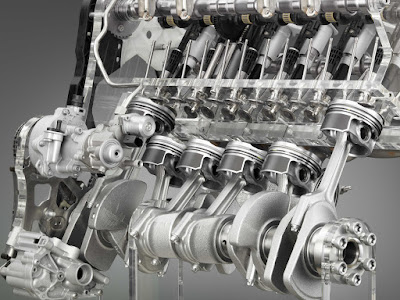

This type of engine, if viewed from the front will resemble a V as the pistons are not vertical, they are slant on either side of the engine. Each side or bank of the engine has it's separate engine head and camshafts. The V will be different angles in different engines but the common angles are 45, 60 and 90 degrees.

An inline 6 cylinder engine

A TOYOTA HIGHLANDER 3MZ ENGINE.

Inline Engine

The inline engine also called I (eg. I6=inline 6 cylinder) because all of the cylinders are inline with each other and the pistons are vertical.

An inline engine can easily accommodate an odd number of cylinders such as 5 cylinder engine or the 3 cylinder engines that may be used in small fuel efficient models.

An inline 6 will be cheaper to build than a V6 engine and there can be less complications in this 6 as there is one engine head for the timing belt or chain to connect to.

V Engine

This type of engine, if viewed from the front will resemble a V as the pistons are not vertical, they are slant on either side of the engine. Each side or bank of the engine has it's separate engine head and camshafts. The V will be different angles in different engines but the common angles are 45, 60 and 90 degrees.

An inline 6 cylinder engine